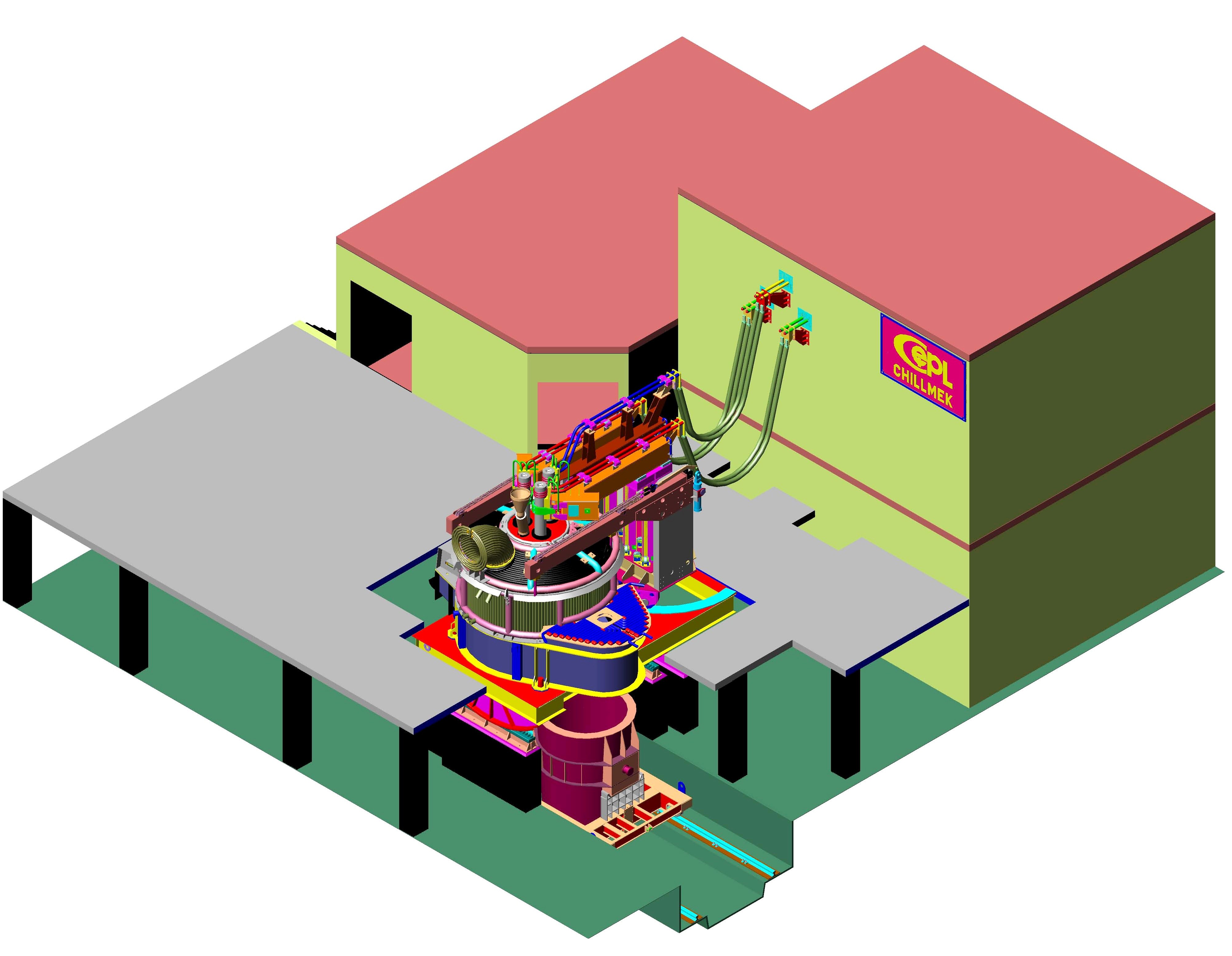

Electric Arc Furnace

Electric Arc Furnace (EAF) was invented in the beginning of 19th century based on principle of short circuiting of electricity.

Electric Arc Furnace (EAF) was invented in the beginning of 19th century based on principle of short circuiting of electricity.

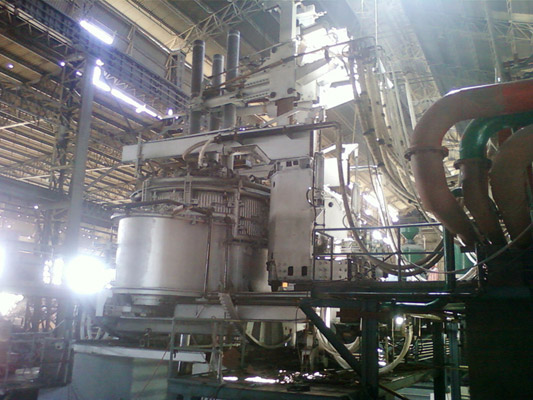

Initially it was introduced in the application of foundry shop starting with the small capacity of 1MT. Afterwards it is widely used for manufacturing of secondary steel up to a capacity of 400MT. EAF is also used in laboratory applications especially where around 3000 degree temperature is required, as well with a minimum temperature as required by different materials and metallurgy.

The basic advantage of EAF over the other melting sources is to produce quality steel as required chemistry & quality specially Sulfur(S)& Phosphorus(P) is reduced to a desirable unit.

The basic advantage of EAF over the other melting sources is to produce quality steel as required chemistry & quality specially Sulfur(S)& Phosphorus(P) is reduced to a desirable unit.

Compared to other melting sources EAF can be operated in an energy efficient manner with the help of Oxygen Lancing in the process. Charged scrap inside the cell is short circuited between the electrodes & scrap to meltdown the metal with a cover on the top followed by the subsequent charges depending on the capacity of the furnace. The flat bath of liquid metal in EAF ensures uniform temperature and homogeneity.