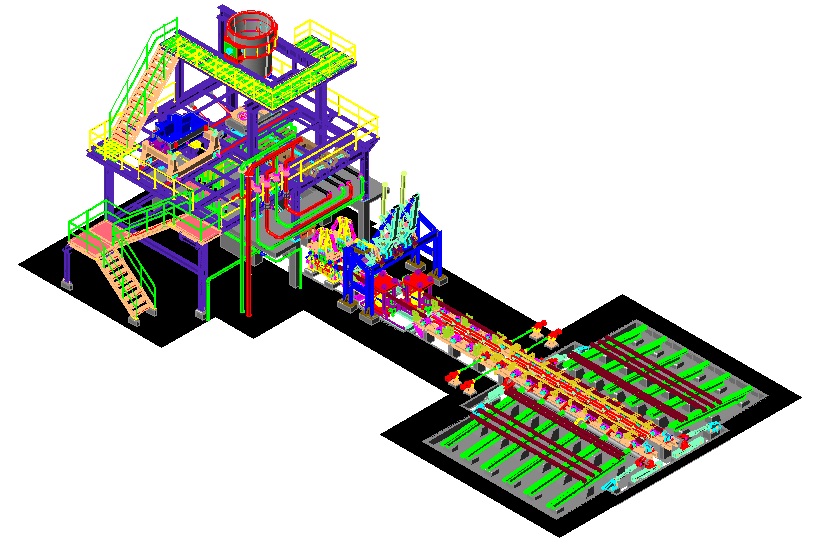

Continuous Casting Machines

The CCM (Continuous Casting Machine) application basically stands out to be the equipment to cast liquid metal in different forms. After melting with required chemistry molten metal is casted in various shapes like Billet, Bloom, Slab, Round, Square or Rectangular.

The CCM (Continuous Casting Machine) application basically stands out to be the equipment to cast liquid metal in different forms. After melting with required chemistry molten metal is casted in various shapes like Billet, Bloom, Slab, Round, Square or Rectangular.

Firstly liquid metal is poured into the Cu Mould Tube of the required section to provide the formation of the section. This liquid metal changes its state to plastic to semi-solid and then to solid.

The solid radial segment is oscillated by Mould Oscillation Table and with the negative strip this particular segment is dragged by the Withdrawal & Straightening Unit in radial form with the help of Dummy Bar through Fixed Bending Sector. After the solid section reaches the Withdrawal point its radius is broken in one or two stages to make it straight by Straightener to boost dragging power and push it towards the roller table.

Now the solid section is cut into desired length and transferred to the Intermediate Roller Table and then to Run-Out Roller Table and finally to Discharge Roller Table to collect it into the Cooling Bed.

Now the solid section is cut into desired length and transferred to the Intermediate Roller Table and then to Run-Out Roller Table and finally to Discharge Roller Table to collect it into the Cooling Bed.

This final casted section is used as raw materials to various industries like Rolling Mill, Section Mill, Plate Mill, Pipe Mill, Automobile Industry and Machine Shops.